包括英特爾、ARM、三星和高通在內的主要IC OEM公司都積極致力于將工藝幾何尺寸降低到10nm甚至7nm的FinFET架構的開發。

艾博康公司推出創新型的無源晶振吸引用戶的關注點ABM11-24.000MHZ-D2X-T3,這一行業趨勢背后的主要驅動力與總消費的減少有關動力,同時提高整體性能。這一努力旨在促進電池驅動的終端解決方案(消費、醫療、物聯網、工業等)的實際實施,在功能豐富的環境中需要極低的功耗,低功耗對于無源晶體來說切入點更加高。然而,這些進步顯著地影響了傳統的時鐘電路。

艾博康公司推出創新型的無源晶振吸引用戶的關注點ABM11-24.000MHZ-D2X-T3,這一行業趨勢背后的主要驅動力與總消費的減少有關動力,同時提高整體性能。這一努力旨在促進電池驅動的終端解決方案(消費、醫療、物聯網、工業等)的實際實施,在功能豐富的環境中需要極低的功耗,低功耗對于無源晶體來說切入點更加高。然而,這些進步顯著地影響了傳統的時鐘電路。

| Manufacturer Part Number 原廠編碼 | Manufacturer廠家 | Series型號 | Type 系列 | Frequency頻率 | Package / Case包裝/封裝 |

| ABM10-26.000MHZ-7-A15-T | Abracon晶振 | ABM10 | MHz Crystal | 26MHz | 4-SMD, No Lead |

| ABM10-40.000MHZ-8-7-A15-T | Abracon晶振 | ABM10 | MHz Crystal | 40MHz | 4-SMD, No Lead |

| ABM3B-28.63636MHZ-10-1-U-T | Abracon晶振 | ABM3B | MHz Crystal | 28.63636MHz | 4-SMD, No Lead |

| ABM3B-40.000MHZ-10-1-U-T | Abracon晶振 | ABM3B | MHz Crystal | 40MHz | 4-SMD, No Lead |

| ABM3B-12.800MHZ-10-1-U-T | Abracon晶振 | ABM3B | MHz Crystal | 12.8MHz | 4-SMD, No Lead |

| ABM3-40.000MHZ-D2Y-F-T | 艾博康晶振 | ABM3 | MHz Crystal | 40MHz | 2-SMD, No Lead |

| ABM3B-24.576MHZ-10-1-U-T | Abracon晶振 | ABM3B | MHz Crystal | 24.576MHz | 4-SMD, No Lead |

| ABM3B-13.000MHZ-10-1-U-T | Abracon晶振 | ABM3B | MHz Crystal | 13MHz | 4-SMD, No Lead |

| ABM9-12.000MHZ-10-D1Y-T | Abracon晶振 | ABM9 | MHz Crystal | 12MHz | 4-SMD, No Lead |

| ABS25-60.000KHZ-T | Abracon晶振 | ABS25 | kHz Crystal (Tuning Fork) | 60kHz | 4-SOJ, 5.50mm pitch |

| ABS25-100.000KHZ-T | Abracon晶振 | ABS25 | kHz Crystal (Tuning Fork) | 100kHz | 4-SOJ, 5.50mm pitch |

| ABM8-37.500MHZ-12-1-U-T | Abracon晶振 | ABM8 | MHz Crystal | 37.5MHz | 4-SMD, No Lead |

| ABM11-24.000MHZ-D2X-T3 | Abracon晶振 | ABM11 | MHz Crystal | 24MHz | 4-SMD, No Lead |

| ABM11-27.000MHZ-D2X-T3 | Abracon晶振 | ABM11 | MHz Crystal | 27MHz | 4-SMD, No Lead |

| ABM10-48.000MHZ-E20-T | Abracon晶振 | ABM10 | MHz Crystal | 48MHz | 4-SMD, No Lead |

| ABM11-26.000MHZ-D2X-T3 | Abracon晶振 | ABM11 | MHz Crystal | 26MHz | 4-SMD, No Lead |

| ABM11-38.400MHZ-D2X-T3 | Abracon晶振 | ABM11 | MHz Crystal | 38.4MHz | 4-SMD, No Lead |

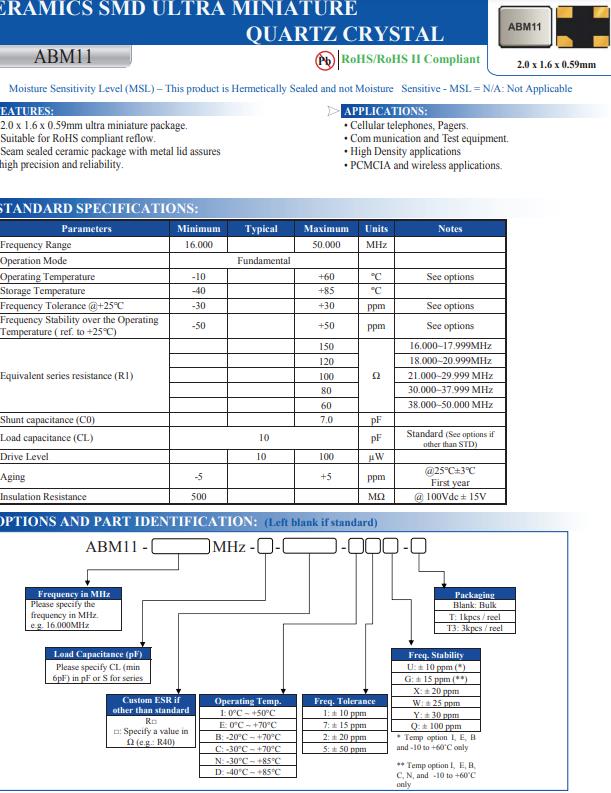

Abracon發布編碼ABM11-24.000MHZ-D2X-T3是一款無源晶振,石英晶振,2.0 x 1.6 x 0.59mm超微型封裝。適用于符合RoHS標準的回流。接縫密封陶瓷包裝與金屬蓋保證高精度、高可靠性,移動電話,尋呼機。通信和測試設備。高密度應用,PCMCIA和無線應用。

The IoT market is on an explosive pace of growth with industry projections of $470 billion for IoT related hardware, software, and other comprehensive solutions. The current installed base of 15.4 billion devices is expected to exceed 30.7 billion by 2020.

Major IC OEM’s including Intel, ARM, Samsung and QUALCOMM are actively engaged in the development of reduced process geometries down to 10nm and even 7nm FinFET architectures.

The primary driving force behind this industry trend is related to the reduction in total consumed

power, while improving overall performance. This effort is being undertaken to facilitate the practical implementation of battery powered end-solutions (consumer, medical, IoT, industrial, etc.), requiring extremely low power in a feature-rich environment. These advancements, however, have significantly impacted the traditional clocking circuit.

As the low power operation becomes paramount, the current mirrors biasing the inverter amplifier stage in the Pierce Oscillator loop are “starving” the amplifier. This approach has a significant impact on the transconductance of the inverter amplifier block which, in-turn, has a profound effect on the forward gain margin (GM) of the closed-loop oscillator circuit.